Access to fresh water is a significant problem for many people around the world. In some areas, severe droughts mean there is no fresh drinking water, and in other people, pollution is so heavy that the water is not drunk. Making fresh drinking water from sea water is possible for a long time, but recent researchers show a new alternative seawater membrane that can make sea water drink in minutes.

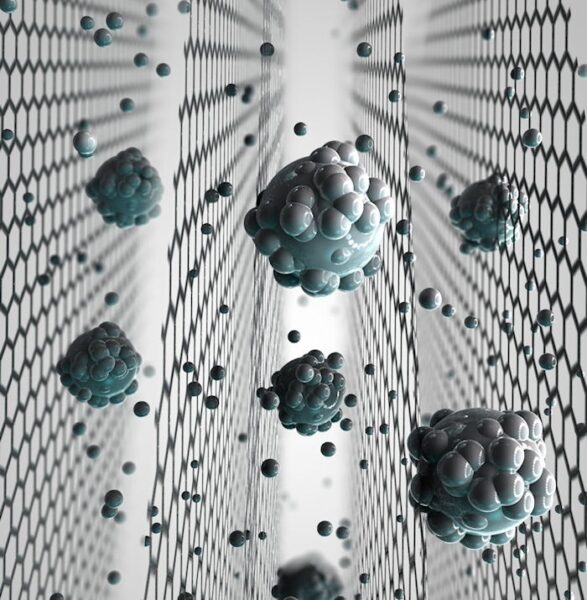

The Institute of Technical Technology and Korean Buildings has announced the development of a stable electrossel nanofiber membrane that can turn seawater into drinking water using a membrane distillation process. Scientists on the project noted that the wetting membrane is the biggest challenge in membrane distillation. If the membrane exhibits wetting during the membrane distillation operation, the membrane must be replaced.

Progressive membrane quamps have been observed in long-term operations, and so membranes are fully moistened, it leads to inefficient distillation performance. Inefficient performance produces low-quality permeate. The research team developed an axial electrosyl nanofiber membrane made using alternative nano technology. Alternative technology is electrospinning, and technology shows the potential to help solve the problem of lack of fresh water throughout the world.

This technology prevents wetting problems and increases long-term stability for membrane distillation processes. The techniques used to produce materials are the most profitable and simple options for making membranes with a three-dimensional hierarchical structure. The team uses the poly vinylidene fluoride-co-hexafluoropropylene as the core and silica airgel mixed with low polymer concentrations as a sheath producing co-axial composite membranes.

They can obtain the surface of the superhydrophobic membrane. The team also noted that Silica Airgel showed a much lower thermal conductivity than conventional polymers which lead to increased water vapor flux during the membrane distillation process. The membrane was carried out on resoba salt 99.99 percent for one month. The team said the membrane was well operated without wetting and polluting the problem.